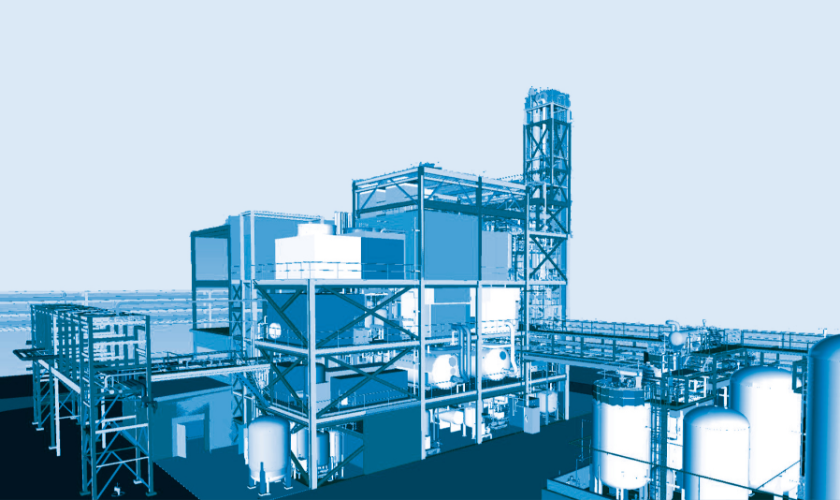

Metathesis – Fragrance production facility, USA

The construction of a metathesis facility in South Carolina, USA, for the production of fragrance ingredients was based on the pilot facility conceived by the customer’s development department at its technical center. The scaling to series production was carried out according to US standards using local service providers.

During the sophisticated chemical process, catalytic ring-opening takes place on packed bed reactors in order to produce a macrocyclic musk aromatic substance. The scope of planning included the industrial tank depot, the recovery of solvents using evaporators and vapor compression, the industrial solution to regenerate the catalyst and the purification of the raw product through distillation.

Scope of services

Regenerative post-combustion

The production of flavors and fragrance ingredients entails a particular challenge: The smell-intensive exhaust air that is generated by a variety of ingredients and ingredient groups that often need to be processed in quick succession during campaigns. Tesium therefore thoroughly researched numerous methods to handle exhaust air, both in technical and economic terms, as part of the project. Thermal oxidation proved to be the best solution because it allows for the organic ingredients that are produced irregularly to be purified in the quickest and safest way.

Tesium chose regenerative instead of thermal post-combustion due to the fact that there were no heat receptors for the latter and thus less additional energy was required. In addition, the planning and construction of the facility created further cost-saving potential for customers because they can now choose between using natural gas or solvents as additional fuel as part of waste processing.

Scope of services

Extraction of natural materials for the food and beverage industry

Tesium has planned and built three facilities for a customer who extracts a very wide variety of high-quality natural materials such as leaves, roots, herbs, spices, peels and seeds. The customer then distills or fractionates the extracts in order to obtain natural extracts, flavors and extractive basic ingredients for the food and beverage industry. In this planning, Tesium took into account the spatial restrictions of inventories and optimally incorporated the facilities into the existing, operational infrastructure and the precise weighing technology.

The project consists of three small extractors or percolators with a volume of 0.25–0.5 m³ that were conceived as a “one-pot facility” for the mostly fibrous plant materials. They simultaneously serve as a distillation bubble that enables the gentle in vacuo distillation and fractionation of the ingredients. They are also equipped with automated dosage weighing technology. The exhaust vapor condensation through the distillation towers takes place in two stages with cooling water and cooling brine. After a construction time of only five months, three facilities spread over three floors with constructional steelwork, steam connections, cooling water and cooling brine, and programmed controls were ready for operation.

Scope of services

Reengineering of a tank depot for organic chemicals in line with the German Federal Water Act

An industrial tank depot for organic raw materials and intermediate products was gradually modernized as part of the project – a typical brownfield engineering project in which the basic construction element was preserved. The modernization took place during production, all requirements of the German Federal Water Act had to be met, containers had to be replaced or equipped with safety technology, and new pipes had to be installed following their reassembly. Furthermore, the facility had a complex infrastructure: Using a fixed pipe system, 48 overground tanks in the depot supply a production building that has twelve reaction and distillation facilities as well as an open-air plant with twelve batch multi-purpose facilities. The reengineering had to guarantee the safety of the entire facility while making sure that ingredients were delivered correctly. For this, Tesium focused on the “pipe railway station,” which connects every process facility with each tank. The employees produced a detailed safety-related assessment and used it as a basis to create an automation concept.

Scope of services

One oil mill, two products: bioenergy and food production

Since 2007, the Ottenstein oil mill, which was planned and built by Tesium, has produced canola oil that is successfully sold as biogenic fuel or heating fuel for combined heat and power plants. The customer wanted to introduce another product as an additional pillar: cold-pressed canola oil, in its essential form as a premium, healthy foodstuff. Tesium optimized the facility in order to be able to also produce premium foodstuffs.

One advantage was that Tesium had already implemented food industry standards in the planning stage of the bioenergy project. In an audit, the oil mill met the stringent requirements of the IFS International Food Standard. After a few technical optimizations by Tesium, the oil mill passed the initial food certification on the first try with the “high level” score. Today, the award-winning cooking oil can be found on supermarket shelves.

Scope of services

Fine chemicals plant: Management upgrade with Siemens PCS 7

The management of a fine chemicals plant had to be upgraded to a new level for Symrise. The requirements were high: The implementation of the process management system required that all possibilities for future process analyses and optimizations be considered in close cooperation with the production department. The yield and production quality had to increase, and the facilities and their process safety had to be optimized. The fact that we were dealing with a multi-purpose facility made the task all the more complex.

Symrise placed great importance not only on being able to see the newly conceived process automation but also on conducting thorough tests beforehand. As a Siemens Solution Partner, Tesium implemented the project in such a way that enabled the seamless conversion to the flexible SIMATIC PCS 7 process control system with the shortest possible downtime.

Scope of services

Sector

Hair care products, detergents and cleaning agents, adhesives and sealants

Project

Refurbishment of a perfume compounding plant according to the Water Resources Act (WHG)

Sector

Confectionery

Project

Plant safety analyses

Sector

Healthcare and agriculture

Project

Details on request

Sector

High-tech polymer materials

Project

Details on request

Sector

Flavours and fragrances, cosmetic raw materials and active ingredients as well as functional ingredients

Project

Numerous projects for process plants and related site infrastructure

Sector

Water treatment chemicals

Project

Hazardous materials storage, further projects on request

Sector

Enamelled copper wires and aluminium wires

Project

Hazardous materials storage (varnish) and various projects

Sector

wood materials

Project

Immission measurements and various planning projects

Sector

logistics

Project

Hazardous materials storage according to Water Resources Act (WHG)